A short History of the Folding bike

Mar 04, 2020Why folding bikes?

Folding bikes are very practical and efficient modes for transport. Steve Jobs once referred to computers as “bicycles for the brain” because they multiply our effort. A human pedalling a bicycle is more efficient than a Condor. A folding bike has the ability to make this amazing efficiency gain portable and ready to empower you whenever necessary.

The beginnings of the folding bicycle: Moulton Bicycles

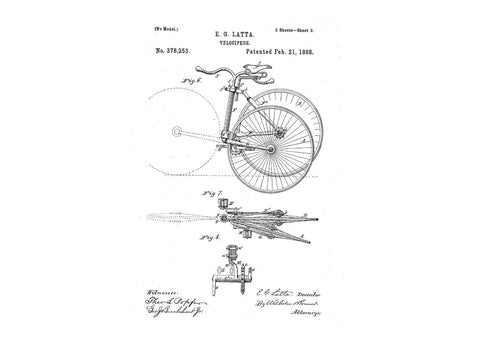

Even though folding bikes seem novel they have a long history. Collapsible bikes have existed ever since the invention of the safety bicycle in 1886. There have been many interesting developments on this front, especially as modes of transport used by the paratroopers. But the history of the modern folding bike started really with the invention of the Moulton Bike, invented by Sir Alex Moulton, which although was not a folding bike, paved the way for small wheel bicycles.

In the late 1950s, disillusioned with the design of the classic bicycle, Alex Moulton set about creating a new design. He thought the classic diamond frame was inconvenient to mount, difficult to adjust for size and not suitable for both sexes, and that 'Ladies' open frame bicycles without the top tube of the diamond frame were structurally compromised for ease of use. He believed that classic bicycles (especially with small frames and smaller wheels known as 'shopper' bicycles) were uncomfortable to ride without the use of wide, low-pressure tyres which increased rolling resistance. He also thought large wheels made a bicycle slow and cumbersome to store, and did not easily fit emerging societal commuting patterns in the developed world, which often combined more than one form of transport.

In November 1962 he showed his newly designed bicycle at the Earl's Court Cycle Show. Having sought for several years to market an innovative design, he had discussed with Raleigh the possibility of collaborating with the company. When the negotiations did not work out, he decided to go it alone and set up Moulton Bicycles Ltd. The bicycle historian Tony Hadland said: "In the bicycle world this was the equivalent of Decca turning down the Beatles."

The basic concept of the bicycle had remained pretty much unchanged since Victorian times. With its small wheels, high saddle and rubber suspension, Moulton's design was a radical departure from this traditional shape. He explained in a later interview that the Moulton F-frame cycle design was "born out of my resolve to challenge and improve upon the classic bicycle, with its diamond frame and large wheels, which has locked bicycle design into that form since the pioneering work in England of Starley and others at the end of the 19th century."

Moulton considered that small wheels with high-pressure tyres would result in less rolling resistance, less inertia and hence greater acceleration. He then went on to develop a range of high-pressure tyres in cooperation with Dunlop.

A month after the launch, the cyclist John Woodburn broke the Cardiff-to-London record on the company's "Speed" model, averaging 24 miles per hour over a distance of 162 miles and keeping the Moulton name firmly in the public imagination while proving that small wheels can be faster than traditional wheels.

An adaptation: the Raleigh Twenty

Raleigh, being convinced by the success of the Moulton bike, purchased the rights to produce the bikes. One of Raleigh's answers to the Moulton was the Raleigh Twenty, also known as the Raleigh Shopper, and sold under some of Raleigh's other captive brand names. Some also were made in Canada and New Zealand.

The Twenty was not nearly as sophisticated a design as the Moulton, but there was a visual resemblance. With an important difference, the frame had a simple middle hinge that allowed the bike to be folded in half and stored away. This design was and still is one of the most popular hinge designs in folding bikes. While the Twenty lacked the Moulton's full suspension, it was inexpensive and rugged and fun to ride. The 20-inch wheels were easy to get tires for, and the tires held up quite well. The Twenty superficially resembles many inexpensive European 20-inch folders of the era, but the frame and hinge are much more solid than with most of these.

The next iteration of folding bikes: Bickerton Bicycles

Following the success of the Raleigh 20 and similar models, Harry Bickerton was inspired to create the Bickerton Portable. The bicycle was made entirely of aluminium profiles, without any welds.

The bike has an interesting fold, The handlebars are a telescopic bullhorn design and the bike breaks in the middle. The Front wheel is smaller than the rear and the whole thing folds on itself. The bike has many clamps and levers which make the bike fold down to a fairly compact size.

In its weight and folded package size it broke new ground and it was what inspired Andrew Ritchie in creating the next iteration of folding bike after a visit at Harry’s workshop in Dorset.

Brompton comes to life

In 1976, Andrew Ritchie founded a bicycle company named after the Brompton Oratory. Ritchie obtained backing from friends and sought to license the design, but after five years began manufacturing the bicycle design himself and by early 1988 Brompton Bicycles entered mass manufacture.

The Brompton is an evolution of the Bickerton folding bike, made out of steel, a traditional bike material. The rear wheel folds under and the front wheel covers the chainset. Which makes for a cubic folded shape.

Innovating the folding bike industry: the early days of Hummingbird

Hummingbird takes on the innovations in frame design, high performance wheels and easy foldability and combines them with the high end materials and design techniques of the 21st Century.

Hummingbird was designed by Petre Craciun, who was interested in bikes and, like most urban cyclists, he still recalls coming out of the cinema and finding his pride and joy missing from the bike-stand. He wanted a bike that was a bit less cumbersome, one that could be easily carried inside a cinema, college, or a flat, and all those myriad other buildings from which bicycles are effectively barred.

A folding bike would fit the bill, but Petre was shocked to discover just how heavy the established machines were. So was Ligia, Hummingbird’s co-founder, who had also expressed an interest in getting around by bike, but she lived in a fourth-floor flat with a tiny lift, and like most of us, she simply wasn’t willing or able to struggle upstairs with 12 kilograms of over-engineered folding technology. Petre bought a light, wobbly Bickerton, which more or less did the job, but was far from being the solution they were hoping for. True, it was lighter than most other folding bikes, but it was also extremely wobbly and didn’t feel secure. There had to be a means of combining the satisfactory weight of the Bickerton with a more secure ride.

As his final year project, Petre decided to develop a lightweight folding bike. The key technology would be a one-piece carbon fibre frame, with a CNC-machined aluminium swingarm that could be quick-released - to rotate around the bottom bracket and fold away under the mainframe tube. The swingarm pivot is concentric to the chainset which means the chain/belt is always in tension and thus removing the need for a tensioner - saving weight and removing complexity with a simple design feature.

This simple but rigid core could be equipped with a handlebar stem able to fold back against the frame holding everything together. A carbon seatpost that dropped down through the main frame tube creating a neat and narrow package. Unlike other folding bikes the focus rests on portability and weight hinges, brackets and widgets all add weight, and the accent here was on weight rather than size. That first university prototype weighed 6.5kg.

The future is here: Hummingbird Bicycles today

Since its early days, Hummingbird has grown a lot. Still a small business, Hummingbird is produced in the United Kingdom, sparing no expense to quality and the beauty of the design. With the support of our technical partner, Hummingbird combines all the key attributes of style, innovation and technical excellence that Prodrive stands for.

The engineers at Prodrive hand build and spray each lightweight carbon frame. The composites facility in Milton Keynes which is responsible for our frame production have one goal, to be the best carbon fiber manufacturer in the British industry, as a testament to their success, among their clients include: Aston Martin, Lotus, Bentley, Jaguar Land Rover, McLaren and Overfinch as well as the Defence Ministry.

The final assembly is done at Prodrive HQ, in Banbury, alongside the race and rally cars it builds for Aston Martin, Subaru, Renault and many other championship winning race cars.

The best design paired with the latest technology is what sets our electric folding bikes out from the pack.